1.Urea Formaldehyde (UF) Glue:

UF glue, also known as Urea Formaldehyde, stands out as the go-to synthetic adhesive in plywood production, particularly for interior plywood applications. Its formulation involves the fusion of two key components:

Urea: A crystal-like substance that comes from pee. It’s made of organic stuff, which means it’s from living things.

Formaldehyde: It’s a type of organic stuff that’s a gas. You can tell it’s there by its strong sharp smell.

When these parts mix together, they cause a chemical change making UF sticky. This type of glue has these features:

1.1 Advantages:

- Cheap prices

- Easy-to-use app

- Quick pressing time for plywood

- Sticks things together well

- Works with lots of wood types

UF has a bunch of good points for making plywood, like being cheap and sticking things together well. But let’s not make it all fabulous. One big problem it has is that it doesn’t handle water very well, so when you need plywood that won’t get messed up with moisture, you can’t use it. Also, UF can give off this stuff called formaldehyde sometimes, which might make the plywood weaker. These negative points also have to be considered while choosing the right type of glue for the work in hand, related to making plywood.

1.2 Applications:

The UF glue primarily plays a big role in making these types of plywood:

Interior plywood: Interior plywood is made of the thin layers of wood that are stuck together by means of the UF . Just like particleboard, MDF, and HDF.

Industrial plywood: UF is also super important when making other kinds of industrial plywood, like film-faced plywood and melamine-faced plywood. These special types of plywood are built to last in tough jobs. You’ll see them in building stuff, packaging, and other big industries where they need to be strong resist moisture, and last a long time.

1.3 Conclusion:

UF glue is key to making sure these industrial plywood products are up to snuff for their industries, giving reliable perform

UF doesn’t cost much and it’s easy to use, plus it sticks stuff together well. But it’s not great with moisture and lets out formaldehyde. So, it’s best to use UF glue for making plywood that’ll stay inside and for stuff that doesn’t need to last long or deal with water much.

2. Melamine Urea Formaldehyde (MUF) Glue:

MUF belongs to the class of thermosetting adhesives, and among its main uses, there is the woodworking industry for the fabrication of plywood or particleboard. It is formed by the synthesis between Melamine, Formaldehyde, and Urea.

2.1 Characteristics of MUF Glue:

MUF can connect the layers of wood firmly. This makes plywood products bear the weight and water. It resists high temperatures and is cheaper than PF glue, plus its formaldehyde emission is lower, therefore safe.

2.2 Applications of MUF Glue:

MUF sticks well to lots of things, which makes it great for making furniture that lasts and putting different kinds of wood together. It has a strong grip so people like to use it to make wood stuff that stays together for a long time, whether they’re doing it themselves or making special things. MUF can handle water and heat pretty well so it’s good for furniture that people use every day and that might get wet or hot. If you wish for good bonding of your wood, you can use MUF for your project.

2.3 Classification of MUF Glue:

MUF glue gets sorted by how much Melamine it has in it:

- E0 MUF: This one’s got the most Melamine. It handles moisture and heat the best so people use it when they need something tough.

- E1 MUF: It’s got less Melamine than E0. It’s okay with moisture and heat, but not as good as E0. A lot of folks use it to make plywood for inside stuff.

- E2 MUF: It contains the minimum amount of melamine. It has low resistance to heat and water; hence, it is used in non-structural or low strength applications.

- Phenolic Formaldehyde (PF) Glue

3. Phenolic Formaldehyde (PF)

PF glue has become a mainstay in the wood industry because of toughness and different ways in which it is used in joining various parts of wood.

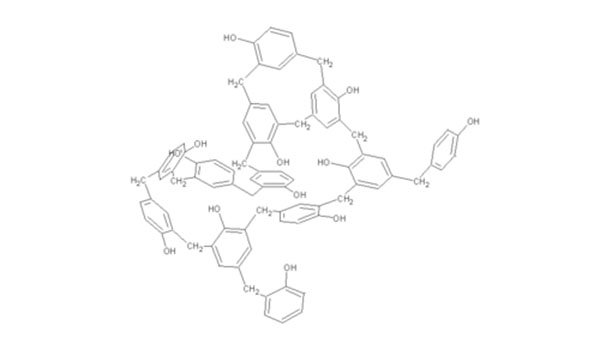

3.1 Composition:

Phenolic formaldehyde glue, more commonly known as PF , is an effective adhesive prepared by the acid-catalyzed reaction of phenol and formaldehyde. It is essentially resistant to moisture or heat and thus provides resistance in joints while working with wood. By comparison, PF is moderately inexpensive and finds applications in plywood that resists moisture, general carpentry, outdoor furniture, and waterproof wooden doors. However, its formaldehyde fumes along with brittleness might place some limitation on the use of PF in woodworking applications.

3.2 Characteristics:

Excellent bonding: The adhesive property of PF is quite prominent. It creates strong and long-lasting joints between the wood parts. Having excellent resistance to moisture and higher temperatures, the PF is suitable for work outdoors or in critically harsher conditions. Also, PF glue is much cheaper compared to other adhesives. Cost-effective, and perfect for several wooden working applications.

3.3 Applications:

Manufacturing of Plywood: One of the most common adhesives used in the production of water-resistant plywood types is PF glue.

Solid Wood Glue-up: In woodworking, PF is utilized for bonding pieces of solid wood that require high strength.

Moisture-Resistant Product Production: PF can be used in moisture-resistant product manufacturing, such as outdoor furniture and water-resistant wooden doors.

3.4 Considerations for PF Glue:

Formaldehyde Emissions: The chemical formaldehyde is an irritant to the eyes, skin, and respiratory tract. While today’s PF do not emit as much formaldehyde into the atmosphere as their forerunners did, it does require proper protective gear and a well-ventilated environment during its application.

Rigidity: PF has low flexibility compared to other adhesives. Hence, joints that need elasticity cannot be joined using this adhesive.

4. Other Glue Types:

Other adhesives used in the manufacture of plywood include PU glue, Epoxy glue, and EVA glue. These options are relatively few in application because of their higher costs or properties that may not exactly coincide with the requirements of the plywood manufacturing application.

5. Selecting the Appropriate Glue:

Picking the right glue depends on a few things, like:

- Purpose of plywood: For indoor use, outdoor projects, or for heavy loads.

- How tough does it need to be: Can it get wet, handle humidity, or withstand tugging and pulling?

- Cost: How much it costs-is the glue within your budget?

- One of the best things you can do is ask plywood makers or persons well-informed on the matter to try and come up with the best glue for what you are trying to do.

6. Reminders:

Follow the manufacturer’s recommendations concerning glue appliances. Consider also appropriate safety measures in any application of this kind of adhesive to avoid skin and eye contact. Keep the adhesives in a well-ventilated area, usually dry, to keep their effectiveness.

7. In conclusion

The adhesives of UF and PF are synthetic resin glues that are made by the combination of organic compounds like urea, phenol reacting with formaldehyde.

The adhesive UF is applied in different applications involving wood and plywood bonds.

The mechanical strength of PF adhesives is much better compared to UF, and heat resistance is usually applied in areas that require hardness or need high thermal resistance, such as structural adhesives or insulation material production.

Are you looking for exquisite industrial plywood? With a wealth of experience, HPC is able to provide a wide range of high-standard products. Contact us today for more information and discover the perfect pieces for your customers!